ٿڌي رولڊ واٽر اسٽاپ Z-شڪل واري اسٽيل شيٽ جو پائل

پيداوار جي سائيز

| سيڪشن | ويڪر | اوچائي | ٿولهه | ڪراس سيڪشنل ايريا | وزن | لچڪدار سيڪشن ماڊيولس | جڙت جو لمحو | ڪوٽنگ ايريا (هر ڍير جي ٻنهي پاسن کان) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (ڊبليو) | (ه) | فلانج (ٽي ايف) | ويب (tw) | هر ڍير تي | ڀت جي حساب سان | |||||

| mm | mm | mm | mm | سينٽي ميٽر/ميٽر | ڪلوگرام/ميٽ | ڪلوگرام/مڪعب ميٽر | سينٽي ميٽر/ميٽ | سي ايم 4/ميٽ | چورس ميٽر/ميٽر | |

| سي آر زي 12-700 | 700 | 440 | 6 | 6 | 89.9 | 49.52 | 70.6 | 1,187 | 26,124 | 2.11 |

| سي آر زي 13-670 | 670 | 303 | 9.5 | 9.5 | 139 | 73.1 | 109.1 | 1,305 | 19,776 | 1.98 |

| سي آر زي 13-770 | 770 | 344 | 8.5 | 8.5 | 120.4 | 72.75 | 94.5 | 1,311 | 22,747 | 2.2 |

| سي آر زي 14-670 | 670 | 304 | 10.5 | 10.5 | 154.9 | 81.49 | 121.6 | 1,391 | 21,148 | 2 |

| سي آر زي 14-650 | 650 | 320 | 8 | 8 | 125.7 | 64.11 | 98.6 | 1,402 | 22,431 | 2.06 |

| سي آر زي 14-770 | 770 | 345 | 10 | 10 | 138.5 | 83.74 | 108.8 | 1,417 | 24,443 | 2.15 |

| سي آر زي 15-750 | 750 | 470 | 7.75 | 7.75 | 112.5 | 66.25 | 88.34 | 1,523 | 35,753 | 2.19 |

| سي آر زي 16-700 | 700 | 470 | 7 | 7 | 110.4 | 60.68 | 86.7 | 1,604 | 37,684 | 2.22 |

| سي آر زي 17-700 | 700 | 420 | 8.5 | 8.5 | 132.1 | 72.57 | 103.7 | 1,729 | 36,439 | 2.19 |

| سي آر زي 18-630 | 630 | 380 | 9.5 | 9.5 | 152.1 | 75.24 | 119.4 | 1,797 | 34,135 | 2.04 |

| سي آر زي 18-700 | 700 | 420 | 9 | 9 | 139.3 | 76.55 | 109.4 | 1,822 | 38,480 | 2.19 |

| سي آر زي 18-630 اين | 630 | 450 | 8 | 8 | 132.7 | 65.63 | 104.2 | 1,839 | 41,388 | 2.11 |

| سي آر زي 18-800 | 800 | 500 | 8.5 | 8.5 | 127.2 | 79.9 | 99.8 | 1,858 | 46,474 | 2.39 |

| سي آر زي 19-700 | 700 | 421 | 9.5 | 9.5 | 146.3 | 80.37 | 114.8 | 1,870 | 39,419 | 2.18 |

| سي آر زي 20-700 | 700 | 421 | 10 | 10 | 153.6 | 84.41 | 120.6 | 1,946 | 40,954 | 2.17 |

| سي آر زي 20-800 | 800 | 490 | 9.5 | 9.5 | 141.2 | 88.7 | 110.8 | 2,000 | 49,026 | 2.38 |

Z-شڪل واري اسٽيل شيٽ جي ڍيرن جي اوچائي (H) عام طور تي 200mm کان 600mm تائين هوندي آهي.

Q235b Z-شڪل واري اسٽيل شيٽ جي ڍيرن جي ويڪر (B) عام طور تي 60mm کان 210mm تائين هوندي آهي.

Z-شڪل واري اسٽيل شيٽ جي ڍيرن جي ٿولهه (t) عام طور تي 6mm کان 20mm تائين هوندي آهي.

*اي ميل موڪليو[اي ميل محفوظ ٿيل]توهان جي منصوبن لاءِ ڪوٽيشن حاصل ڪرڻ لاءِ

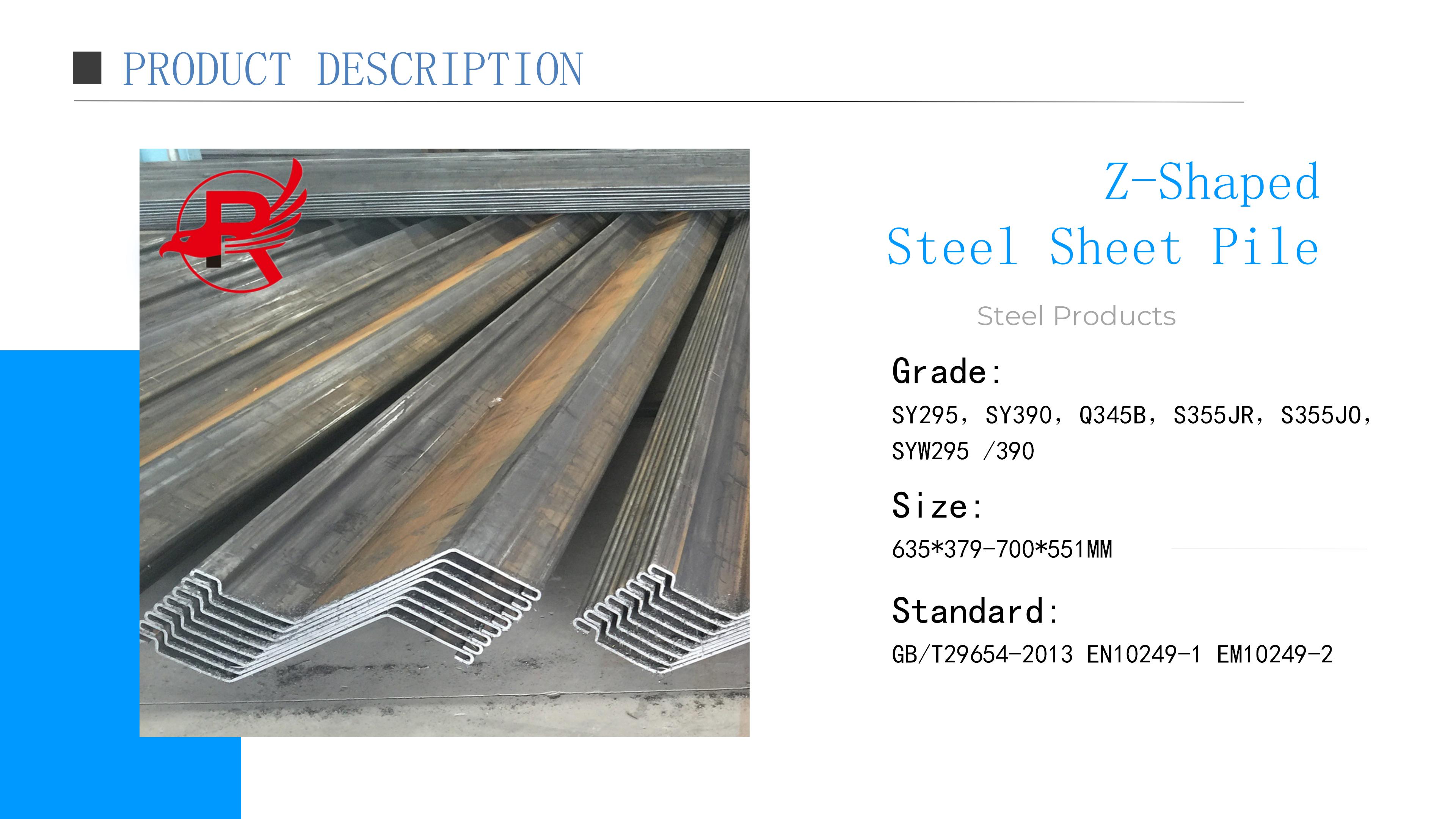

پيداوار جي وضاحت

| شئ جو نالو | |||

| ايم ڪيو ايم | 25 ٽن | ||

| معياري | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. | ||

| ڊيگهه | 1-12m يا توهان جي گهرج جي طور تي | ||

| ويڪر | 20-2500 ميلي يا توهان جي گهرج آهي ته جيئن | ||

| ٿولهه | 0.5 - 30 ملي ميٽر يا توهان جي گهرج جي طور تي | ||

| ٽيڪنڪ | گرم رولڊ يا ٿڌو رولڊ | ||

| مٿاڇري جو علاج | گراهڪ جي گهرجن مطابق صاف، بلاسٽنگ ۽ رنگ سازي | ||

| ٿولهه رواداري | ±0.1 ملي ميٽر | ||

| مواد | سوال195; Q235 (A، B، C، DR)؛ Q345 (B,C,DR); Q345QC Q345QD SPCC SPCD SPCD SPCE ST37 ST12 ST15 DC01 DC02 DC03 DC04 DC05 DC06 20#- 35# 45# 50#، 16Mn-50Mn 30Mn2-50Mn2 20Cr، 20Cr، 40Cr 20CrMnTi 20CrMo; 15CrMo; 30CrMo 35CrMo 42CrMo; 42CrMo4 60Si2mn 65mn 27SiMn; 20Mn; 40Mn2; 50 ملين؛ 1 ڪروڙ 13 2 ڪروڙ 13 3 ڪروڙ 13 -4 ڪروڙ 13؛ | ||

| درخواست | اهو وڏي پيماني تي ننڍن اوزارن، ننڍڙن حصن، لوهه جي تار، سائڊروسفيئر، پل راڊ، فيرول، ويلڊ اسيمبلي، ساختي ڌاتو، ۾ استعمال ٿيندو آهي. ڳنڍڻ وارو راڊ، لفٽنگ ٿلهو، بولٽ، نٽ، اسپنڊل، مينڊريل، ايڪسل، زنجير جو ڦيٿو، گيئر، ڪار جو ڪپلر. | ||

| پيڪنگ برآمد ڪريو | پنروڪ ڪاغذ، ۽ اسٽيل جي پٽي ڀريل. معياري برآمد سمنڊ جي قابل پيڪيج. هر قسم جي ٽرانسپورٽ لاءِ سوٽ، يا ضرورت مطابق | ||

| درخواست | جهاز سازي، سامونڊي اسٽيل پليٽ | ||

| سرٽيفڪيٽ | آئي ايس او، سي اي | ||

| پهچائڻ جو وقت | عام طور تي اڳواٽ ادائيگي جي وصولي کان پوء 10-15 ڏينهن اندر | ||

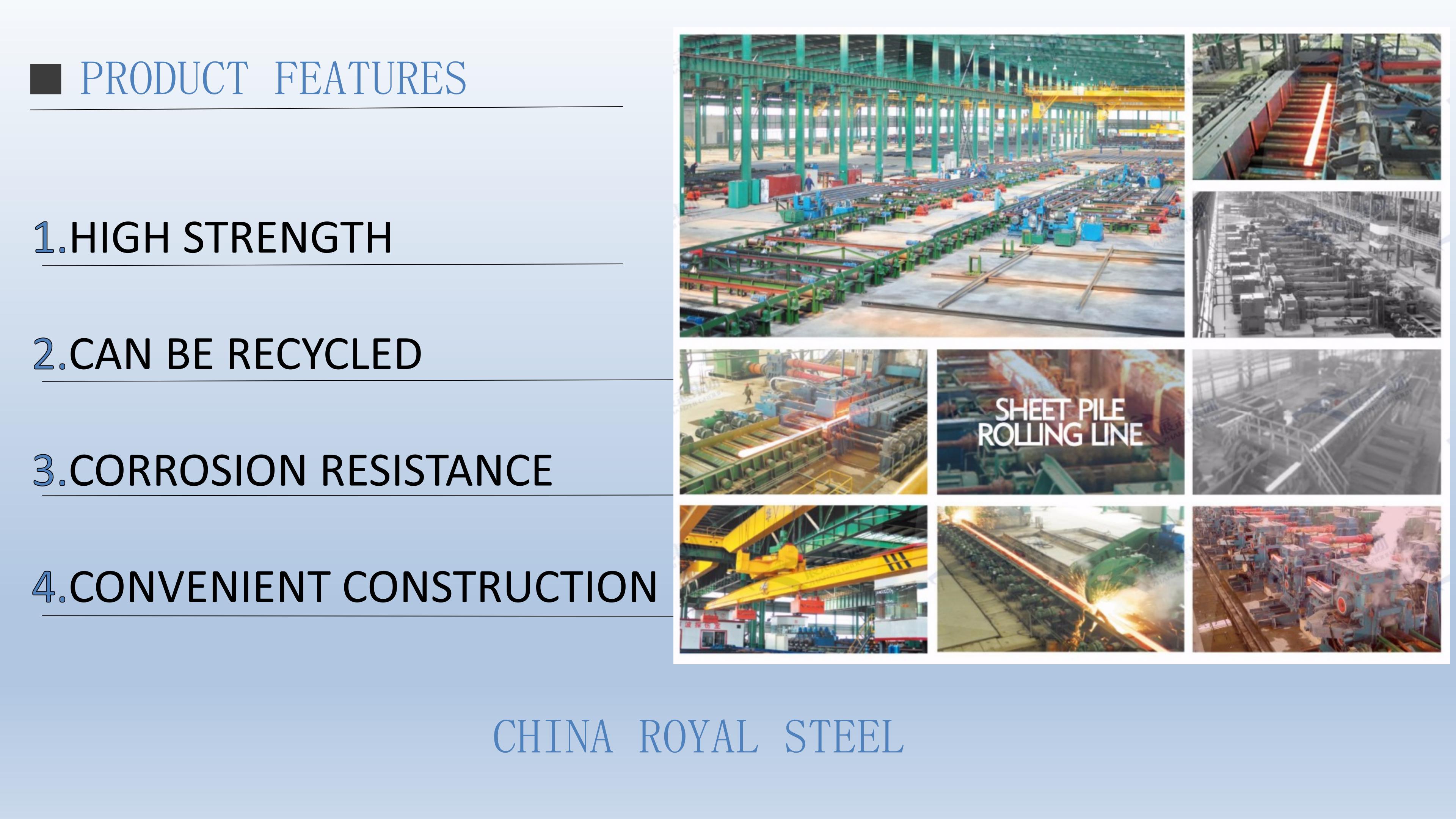

خاصيتون

Z اسٽيل شيٽ پائل، جن کي Z-شڪل واري شيٽ پائل يا Z-پروفائيل پڻ چيو ويندو آهي، عام طور تي مختلف تعميراتي ۽ انفراسٽرڪچر منصوبن ۾ استعمال ٿيندا آهن. هتي Z اسٽيل شيٽ پائل جون ڪجهه خاصيتون آهن:

شڪل:Z اسٽيل شيٽ جا ڍيرانهن ۾ هڪ مخصوص Z-شڪل وارو ڪراس سيڪشن آهي. هي شڪل بهترين ساخت جي طاقت ۽ استحڪام فراهم ڪري ٿي، جيڪا انهن کي مختلف ايپليڪيشنن لاءِ موزون بڻائي ٿي، جنهن ۾ برقرار رکڻ واريون ڀتيون، ڪوفرڊيم، ٻوڏ کان بچاءُ، ۽ گهري کوٽائي شامل آهن.

انٽرلاڪنگ ڊيزائن: Z اسٽيل شيٽ جي ڍڳن ۾ ٻنهي پاسن سان انٽرلاڪنگ ميڪانيزم آهن، جيڪي انهن کي بيحد هڪٻئي سان ڳنڍڻ جي اجازت ڏين ٿا. هي انٽرلاڪنگ ڊيزائن انفرادي ڍڳن جي وچ ۾ هڪ سخت ۽ پاڻي کان بچاءُ وارو ڪنيڪشن فراهم ڪري ٿو، استحڪام کي يقيني بڻائي ٿو ۽ پاڻي جي داخل ٿيڻ کي روڪي ٿو.

اعليٰ طاقت: Z اسٽيل شيٽ جا ڍير اعليٰ معيار جي اسٽيل مان ٺاهيا ويندا آهن، جيڪو غير معمولي طاقت ۽ استحڪام پيش ڪري ٿو. اهو انهن کي ڳري بار برداشت ڪرڻ، خرابي جي مزاحمت ڪرڻ، ۽ سخت ماحولياتي حالتن کي برداشت ڪرڻ جي اجازت ڏئي ٿو.

ورسٽائلٽي:Z اسٽيل شيٽ جا ڍيرمختلف سائزن ۽ طاقتن ۾ اچن ٿا، ڊيزائن ۽ استعمال ۾ لچڪ جي اجازت ڏين ٿا. اهي عارضي ۽ مستقل ٻنهي ڍانچن ۾ استعمال ٿي سگهن ٿا، ۽ انهن جي ماڊيولر نوعيت انهن کي مختلف منصوبي جي گهرجن لاءِ موزون بڻائي ٿي.

آسان تنصيب: Z اسٽيل شيٽ جا ڍير تيز ۽ ڪارآمد تنصيب لاءِ ٺهيل آهن. انهن کي وائبريٽري هيمر يا هائيڊروولڪ پريس استعمال ڪندي زمين ۾ هلائي سگهجي ٿو، انسٽاليشن لاءِ گهربل وقت ۽ محنت کي گهٽائي ٿو.

قيمت جي اثرائتي: Z اسٽيل شيٽ جا ڍير برقرار رکڻ واري ڀتين ۽ ساڳين اڏاوتن جي تعمير لاءِ هڪ قيمت جي اثرائتي حل پيش ڪن ٿا. انهن جي اعليٰ طاقت ۽ ڊگهي سروس لائف بار بار متبادل يا مرمت جي ضرورت کي گهٽائي ٿي، جنهن جي نتيجي ۾ منصوبي جي عمر دوران قيمت جي بچت ٿيندي آهي.

ماحولياتي فائدا: Z اسٽيل شيٽ جا ڍير هڪ پائيدار انتخاب آهن ڇاڪاڻ ته انهن کي پنهنجي سروس جي زندگي کان پوءِ ري سائيڪل ۽ ٻيهر استعمال ڪري سگهجي ٿو. ان کان علاوه، برقرار رکڻ واري اڏاوتن ۾ انهن جو استعمال زمين جي استعمال کي گهٽائي سگهي ٿو ۽ ماحول تي اثر کي گهٽائي سگهي ٿو.

درخواست

زيڊ اسٽيل شيٽ جي ڍڳن ۾ سول انجنيئرنگ ۽ تعمير ۾ وسيع ايپليڪيشنون آهن. ڪجھ عام ايپليڪيشنون شامل آهن:

- برقرار رکڻ واريون ڀتيون:Z اسٽيل شيٽ جا ڍير عام طور تي مختلف بلندين تي مٽي يا ٻين مواد کي مستحڪم ۽ سهارو ڏيڻ لاءِ برقرار رکڻ واري ڀتين جي تعمير ۾ استعمال ٿيندا آهن. اهي مٽي جي ڪٽڻ ۽ پس منظر جي دٻاءُ جي خلاف هڪ محفوظ رڪاوٽ فراهم ڪن ٿا جڏهن ته ضرورت هجي ته موثر تنصيب ۽ هٽائڻ جي اجازت ڏين ٿا.

- ڪوفرڊيمز:Z اسٽيل شيٽ جا ڍير اڪثر ڪري پاڻي جي ذخيرن ۾ تعميراتي منصوبن لاءِ عارضي ڪوفرڊيم ٺاهڻ لاءِ استعمال ڪيا ويندا آهن. ڍير جي انٽر لاڪنگ ڊيزائن هڪ پاڻي بند سيل کي يقيني بڻائي ٿي، جيڪا پاڻي کي صاف ڪرڻ جي اجازت ڏئي ٿي ۽ خشڪ ڪم ڪندڙ علائقي ۾ تعميراتي سرگرمين کي فعال بڻائي ٿي.

- گهري کوٽائي:Z اسٽيل شيٽ جا ڍير گہرے کوٽائي جي مدد لاءِ استعمال ڪيا ويندا آهن، جهڙوڪ بيسمنٽ يا زير زمين اڏاوتن جي تعمير لاءِ. اهي ساخت جي استحڪام فراهم ڪن ٿا، مٽي جي حرڪت کي روڪين ٿا، ۽ کوٽائي واري علائقي ۾ پاڻي جي وهڪري جي خلاف حفاظتي رڪاوٽ طور ڪم ڪن ٿا.

- ٻوڏ کان بچاءُ:زيڊ اسٽيل شيٽ جا ڍير اڪثر ڪري ٻوڏ کان بچاءُ واري نظام ۾ دريائن جي ڪنارن، ليوز ۽ ٻين ٻوڏ جي خاتمي جي جوڙجڪ کي مضبوط ۽ محفوظ بڻائڻ لاءِ استعمال ڪيا ويندا آهن. ڍير جي طاقت ۽ ناقابل تسخيريت پاڻي جي قوتن جي مزاحمت ڪرڻ، ڪٽاؤ کي روڪڻ ۽ ٻوڏ ڪنٽرول قدمن جي سالميت کي يقيني بڻائڻ ۾ مدد ڪري ٿي.

- پاڻيءَ جي ڪناري جون اڏاوتون:زيڊ اسٽيل شيٽ جا ڍير عام طور تي گهاٽن جي ڀتين، جيٽي، مرينا ۽ ٻين واٽر فرنٽ اڏاوتن جي تعمير ۾ استعمال ٿيندا آهن. ڍير استحڪام ۽ مدد فراهم ڪن ٿا، جيڪي جهازن ۽ بندرگاهن جي سهولتن جي محفوظ ۽ ڪارآمد آپريشن جي اجازت ڏين ٿا.

- پل جي چوٽيون:Z اسٽيل شيٽ جي ڍيرن کي پل جي تعمير ۾ ابٽمنٽس طور استعمال ڪيو ويندو آهي، پل جي بنيادن کي سپورٽ ۽ استحڪام فراهم ڪندا آهن.

- مٽي ۽ ڍلون جي استحڪام:زيڊ اسٽيل شيٽ جا ڍير مٽي ۽ ڍلون جي استحڪام لاءِ استعمال ڪيا ويندا آهن، خاص طور تي انهن علائقن ۾ جيڪي لينڊ سلائيڊنگ يا ڪٽاءُ جو شڪار آهن. اهي مٽي جي حرڪت کي روڪڻ ۾ مدد ڪري سگهن ٿا ۽ بندن، ٽڪرين ۽ ٻين ڍلون کي استحڪام فراهم ڪري سگهن ٿا.

![0$NU_O5TD8Y4}`E3UXEVP]2](http://www.chinaroyalsteel.com/uploads/0NU_O5TD8Y4E3UXEVP2.jpg)

پيڪنگ ۽ شپنگ

پيڪنگنگ:

شيٽ جي ڍيرن کي محفوظ طريقي سان اسٽيڪ ڪريو: Z-شڪل واري شيٽ جي ڍيرن کي هڪ صاف ۽ مستحڪم اسٽيڪ ۾ ترتيب ڏيو، يقيني بڻايو ته اهي ڪنهن به عدم استحڪام کي روڪڻ لاءِ صحيح طرح سان ترتيب ڏنل آهن. اسٽيڪ کي محفوظ ڪرڻ ۽ ٽرانسپورٽ دوران منتقلي کي روڪڻ لاءِ اسٽريپنگ يا بينڊنگ استعمال ڪريو.

حفاظتي پيڪنگ مواد استعمال ڪريو: چادر جي ڍيرن جي ڍير کي نمي جي مزاحمتي مواد، جهڙوڪ پلاسٽڪ يا پنروڪ پيپر سان ويڙهايو، ته جيئن انهن کي پاڻي، نمي ۽ ٻين ماحولياتي عنصرن جي نمائش کان بچائي سگهجي. اهو زنگ ۽ زنگ کي روڪڻ ۾ مدد ڪندو.

شپنگ:

نقل و حمل جو مناسب طريقو چونڊيو: شيٽ جي ڍيرن جي مقدار ۽ وزن تي منحصر ڪري، نقل و حمل جو مناسب طريقو چونڊيو، جهڙوڪ فليٽ بيڊ ٽرڪون، ڪنٽينر، يا جهاز. فاصلو، وقت، قيمت، ۽ نقل و حمل لاءِ ڪنهن به ريگيوليٽري گهرجن جهڙن عنصرن تي غور ڪريو.

مناسب کڻڻ جو سامان استعمال ڪريو: U-شڪل واري اسٽيل شيٽ جي ڍيرن کي لوڊ ۽ ان لوڊ ڪرڻ لاءِ، مناسب کڻڻ جو سامان استعمال ڪريو جهڙوڪ ڪرين، فورڪ لفٽ، يا لوڊر. پڪ ڪريو ته استعمال ٿيل سامان ۾ شيٽ جي ڍيرن جي وزن کي محفوظ طريقي سان سنڀالڻ جي ڪافي صلاحيت آهي.

لوڊ کي محفوظ ڪريو: ٽرانسپورٽ گاڏي تي شيٽ جي ڍڳن جي پيڪيج ٿيل اسٽيڪ کي اسٽريپنگ، بريسنگ، يا ٻين مناسب طريقن سان صحيح طرح سان محفوظ ڪريو ته جيئن ٽرانزٽ دوران منتقل ٿيڻ، سلائڊنگ، يا گرڻ کان بچي سگهجي.

پيداوار جي پيداوار جو عمل

ٿڌي ٺهيل Z-شڪل واري اسٽيل شيٽ جي ڍڳن جي پيداوار جي عمل ۾ عام طور تي هيٺيان مرحلا شامل آهن:

مواد جي تياري: اسٽيل پليٽ مواد چونڊيو جيڪي گهرجن کي پورو ڪن، عام طور تي گرم رولڊ يا ٿڌي رولڊ اسٽيل پليٽون، ۽ ڊيزائن جي گهرجن ۽ معيارن مطابق مواد چونڊيو.

ڪٽڻ: اسٽيل پليٽ کي ڊيزائن جي گهرجن مطابق ڪٽيو ته جيئن اسٽيل پليٽ خالي حاصل ڪري سگهجي جيڪا ڊيگهه جي گهرجن کي پورو ڪري.

ٿڌي موڙ: ڪٽيل اسٽيل پليٽ خالي کي فارمنگ پروسيسنگ لاءِ ٿڌي موڙ ٺاهڻ واري مشين ڏانهن موڪليو ويندو آهي. اسٽيل پليٽ کي رولنگ ۽ موڙ جهڙين عملن ذريعي Z-شڪل جي ڪراس سيڪشن ۾ ٿڌو موڙيو ويندو آهي.

ويلڊنگ: ٿڌي ٺهيل Z-شڪل واري اسٽيل شيٽ جي ڍيرن کي ويلڊ ڪريو ته جيئن پڪ ٿئي ته انهن جا ڪنيڪشن مضبوط ۽ نقص کان پاڪ آهن.

مٿاڇري جو علاج: ويلڊ ٿيل Z-شڪل واري اسٽيل شيٽ جي ڍيرن تي مٿاڇري جو علاج ڪيو ويندو آهي، جهڙوڪ زنگ هٽائڻ، پينٽنگ، وغيره، ان جي سنکنرن مخالف ڪارڪردگي کي بهتر بڻائڻ لاءِ.

معائنو: پيدا ٿيل ٿڌي ٺهيل Z-شڪل واري اسٽيل شيٽ جي ڍڳن تي معيار جو معائنو ڪريو، جنهن ۾ ظاهري معيار، طول و عرض جي انحراف، ويلڊنگ جي معيار وغيره جو معائنو شامل آهي.

پيڪنگ ۽ ڪارخاني مان نڪرڻ: قابليت واري ٿڌي شڪل واري Z-شڪل واري اسٽيل شيٽ جي ڍڳن کي پيڪ ڪيو ويندو آهي، پراڊڪٽ جي معلومات سان نشان لڳايو ويندو آهي، ۽ اسٽوريج لاءِ ڪارخاني کان ٻاهر موڪليو ويندو آهي.

*اي ميل موڪليو[اي ميل محفوظ ٿيل]توهان جي منصوبن لاءِ ڪوٽيشن حاصل ڪرڻ لاءِ

ڪسٽمر وزٽ جو عمل

جڏهن ڪو گراهڪ ڪنهن پراڊڪٽ کي ڏسڻ چاهيندو آهي، ته عام طور تي هيٺيان قدم ترتيب ڏئي سگهجن ٿا:

گهمڻ لاءِ ملاقات جو وقت مقرر ڪريو: گراهڪ پراڊڪٽ جي زيارت لاءِ وقت ۽ جڳهه لاءِ ملاقات جو وقت مقرر ڪرڻ لاءِ اڳواٽ ٺاهيندڙ يا سيلز نمائندي سان رابطو ڪري سگهن ٿا.

هڪ گائيڊڊ ٽوئر جو بندوبست ڪريو: گراهڪن کي پيداوار جي عمل، ٽيڪنالاجي ۽ معيار جي ڪنٽرول جي عمل کي ڏيکارڻ لاءِ پيشه ور ماڻهن يا سيلز نمائندن کي ٽوئر گائيڊ طور ترتيب ڏيو.

پراڊڪٽس ڏيکاريو: دوري دوران، گراهڪن کي مختلف مرحلن تي پراڊڪٽس ڏيکاريو ته جيئن گراهڪ پيداوار جي عمل ۽ شين جي معيار کي سمجهي سگهن.

سوالن جا جواب ڏيو: دوري دوران، گراهڪن جا مختلف سوال ٿي سگهن ٿا، ۽ ٽور گائيڊ يا سيلز نمائندي کي صبر سان انهن جا جواب ڏيڻ گهرجن ۽ لاڳاپيل ٽيڪنيڪل ۽ معياري معلومات فراهم ڪرڻ گهرجي.

نمونا فراهم ڪريو: جيڪڏهن ممڪن هجي ته، گراهڪن کي پراڊڪٽ جا نمونا فراهم ڪري سگهجن ٿا ته جيئن گراهڪ پراڊڪٽ جي معيار ۽ خاصيتن کي وڌيڪ سمجهه سان سمجهي سگهن.

فالو اپ: دوري کان پوءِ، گراهڪن جي راءِ ۽ ضرورتن تي فوري طور تي فالو اپ ڪريو ته جيئن گراهڪن کي وڌيڪ مدد ۽ خدمتون مهيا ڪري سگهجن.

جڏهن ڪو گراهڪ ڪنهن پراڊڪٽ کي ڏسڻ چاهيندو آهي، ته عام طور تي هيٺيان قدم ترتيب ڏئي سگهجن ٿا:

گهمڻ لاءِ ملاقات جو وقت مقرر ڪريو: گراهڪ پراڊڪٽ جي زيارت لاءِ وقت ۽ جڳهه لاءِ ملاقات جو وقت مقرر ڪرڻ لاءِ اڳواٽ ٺاهيندڙ يا سيلز نمائندي سان رابطو ڪري سگهن ٿا.

هڪ گائيڊڊ ٽوئر جو بندوبست ڪريو: گراهڪن کي پيداوار جي عمل، ٽيڪنالاجي ۽ معيار جي ڪنٽرول جي عمل کي ڏيکارڻ لاءِ پيشه ور ماڻهن يا سيلز نمائندن کي ٽوئر گائيڊ طور ترتيب ڏيو.

پراڊڪٽس ڏيکاريو: دوري دوران، گراهڪن کي مختلف مرحلن تي پراڊڪٽس ڏيکاريو ته جيئن گراهڪ پيداوار جي عمل ۽ شين جي معيار کي سمجهي سگهن.

سوالن جا جواب ڏيو: دوري دوران، گراهڪن جا مختلف سوال ٿي سگهن ٿا، ۽ ٽور گائيڊ يا سيلز نمائندي کي صبر سان انهن جا جواب ڏيڻ گهرجن ۽ لاڳاپيل ٽيڪنيڪل ۽ معياري معلومات فراهم ڪرڻ گهرجي.

نمونا فراهم ڪريو: جيڪڏهن ممڪن هجي ته، گراهڪن کي پراڊڪٽ جا نمونا فراهم ڪري سگهجن ٿا ته جيئن گراهڪ پراڊڪٽ جي معيار ۽ خاصيتن کي وڌيڪ سمجهه سان سمجهي سگهن.

فالو اپ: دوري کان پوءِ، گراهڪن جي راءِ ۽ ضرورتن تي فوري طور تي فالو اپ ڪريو ته جيئن گراهڪن کي وڌيڪ مدد ۽ خدمتون مهيا ڪري سگهجن.

سوال

سوال: ڇا توهان واپاري ڪمپني يا ٺاهيندڙ آهيو؟

الف: اسان ٺاهيندڙ آهيون، پنهنجي گودام ۽ واپاري ڪمپني سان.

سوال: توهان جي پهچائڻ جو وقت ڪيترو ڊگهو آهي؟

ج: عام طور تي جيڪڏهن سامان اسٽاڪ ۾ هجي ته 5-10 ڏينهن هوندا آهن.يا جيڪڏهن سامان اسٽاڪ ۾ نه هجي ته 15-20 ڏينهن، آرڊر جي مقدار مطابق.

سوال: ڇا توهان نموني مهيا ڪندا آهيو؟ڇا اهو مفت آهي يا اضافي قيمت؟

نواب خير بخش مري: ها، اسان نموني مفت ۾ فراهم ڪندا آهيون، گراهڪ مال جي چارج برداشت ڪندو آهي.

سوال: توهان جي ايم ڪيو ايم بابت ڇا؟

الف: 1 ٽن قابل قبول آهي، ڪسٽمائيز پراڊڪٽ لاءِ 3-5 ٽن.